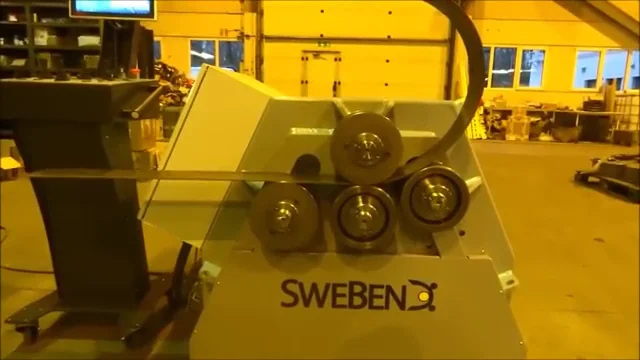

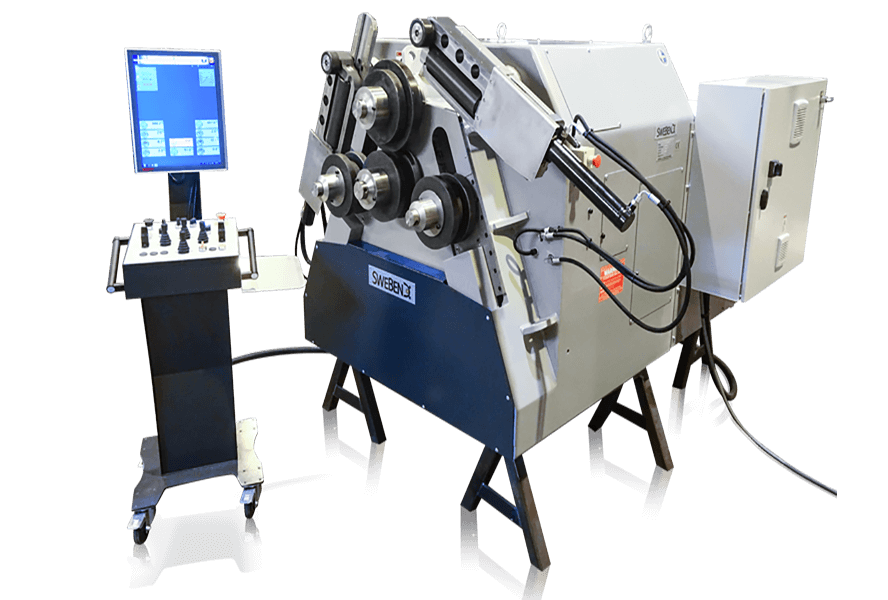

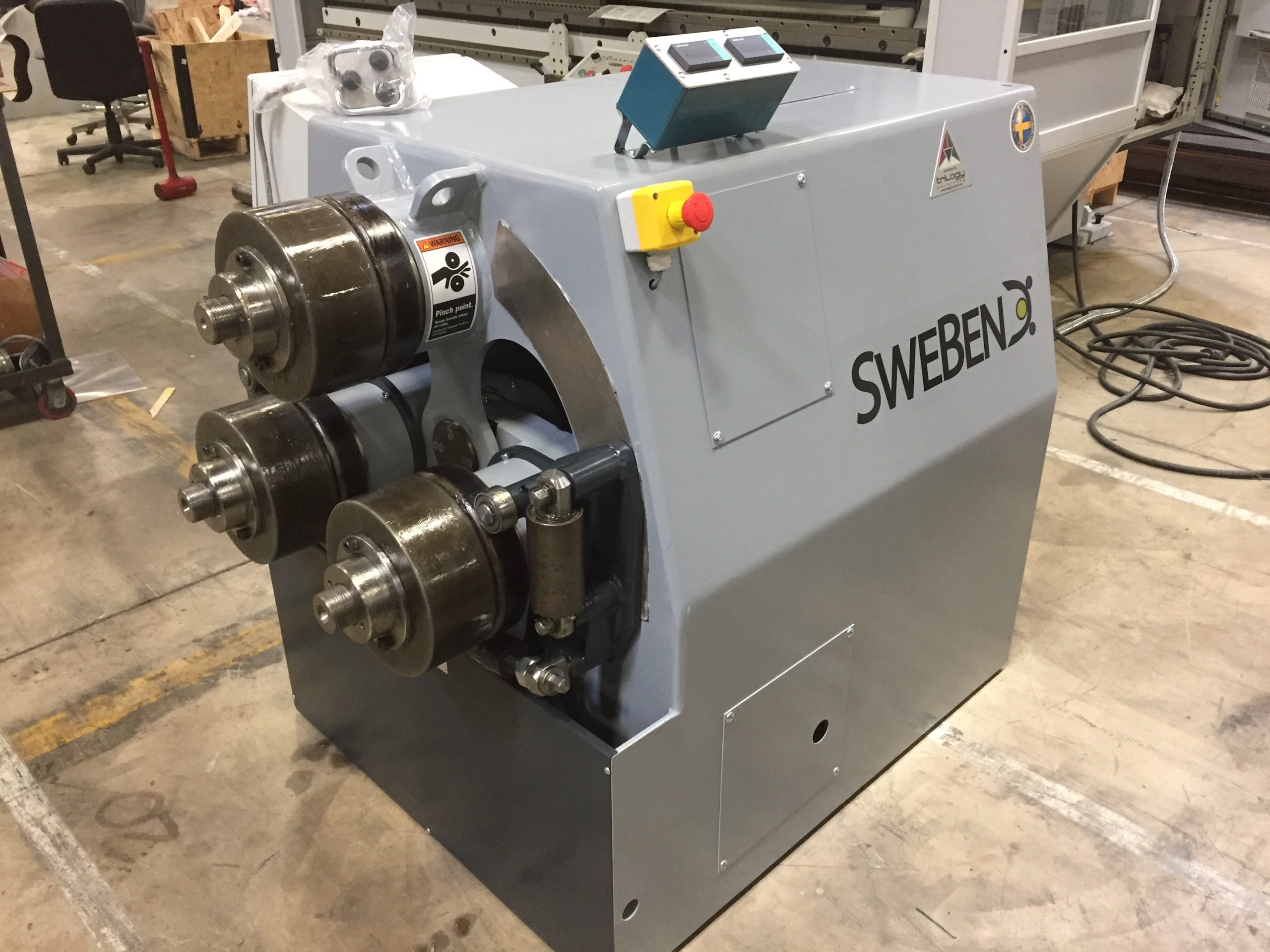

SB3 Series

Three-Roll Angle Roll

The SB3 series is the perfect angle roll for various applications, featuring universal tooling and a wide capacity range.

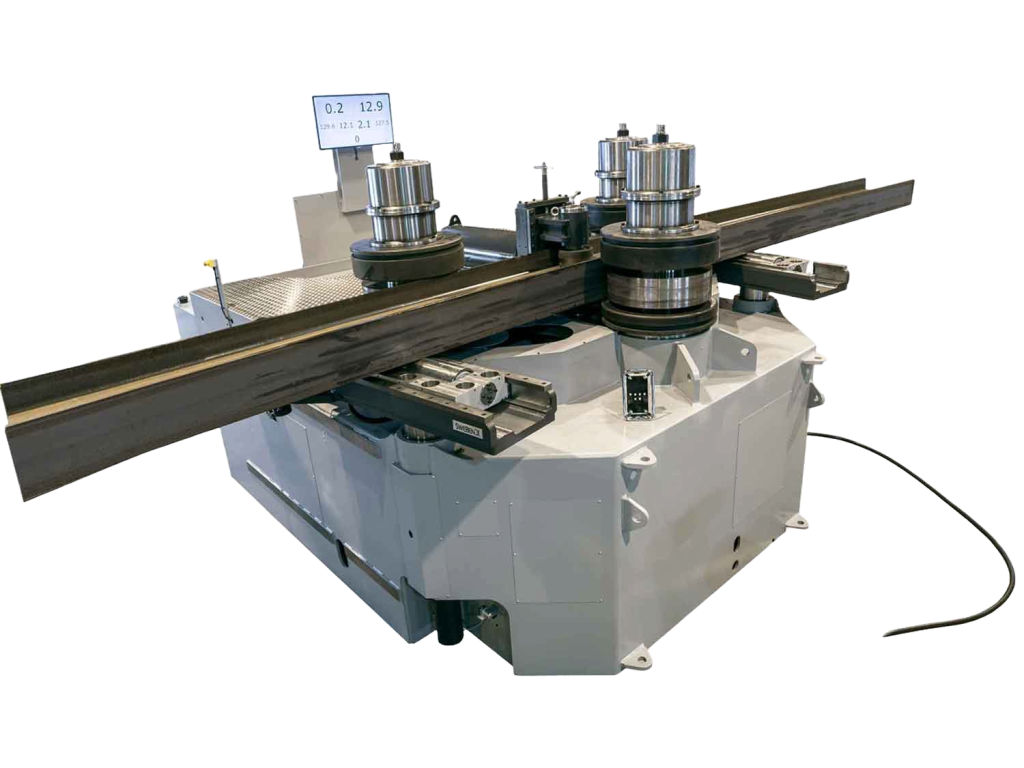

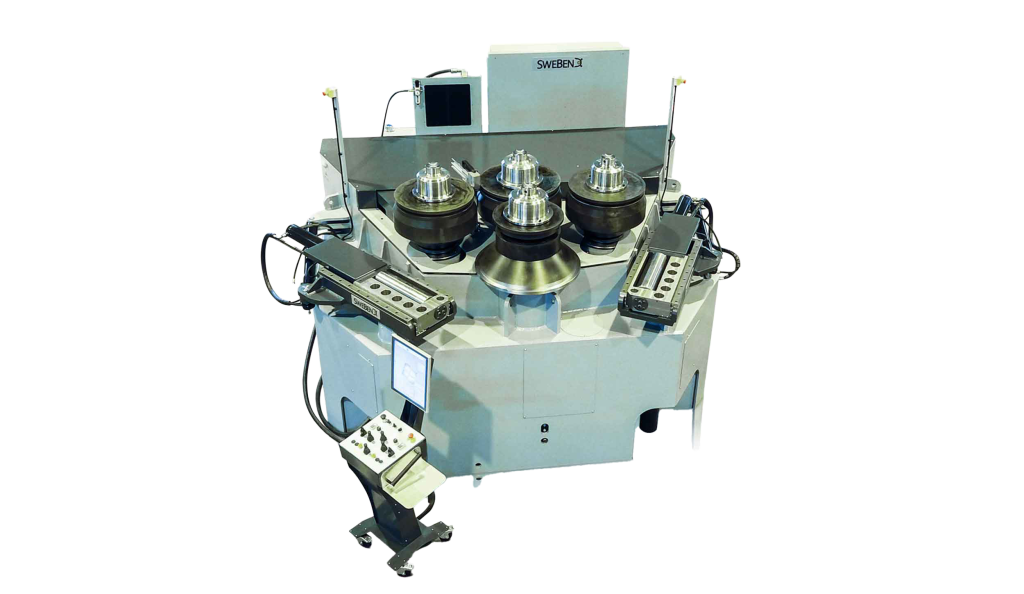

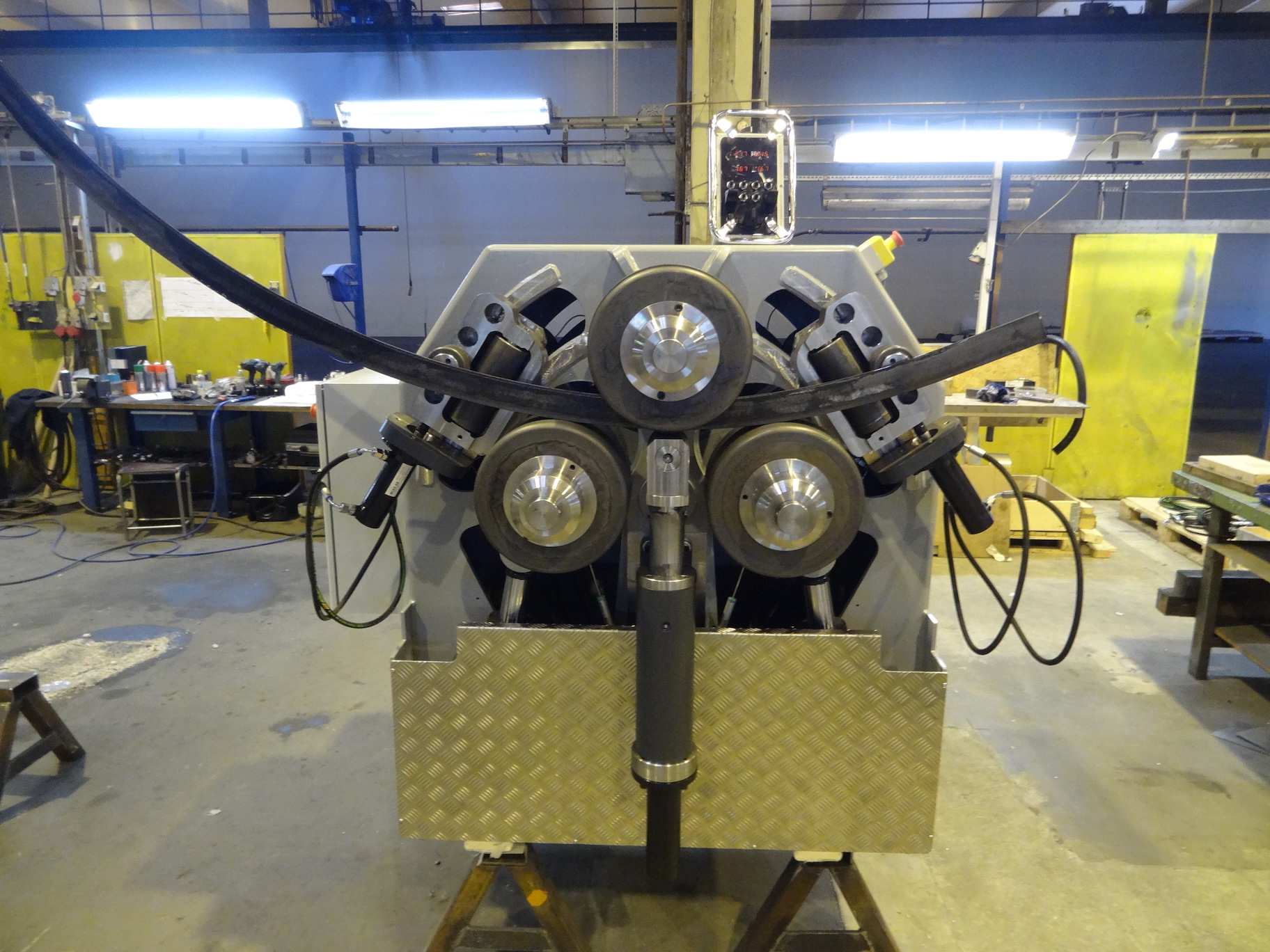

SB4 Series

FOUR-Roll Angle Roll

Ideal for use with SweBend’s Seven CNC control, the four-roll angle rolls give you even greater advantages and performance.

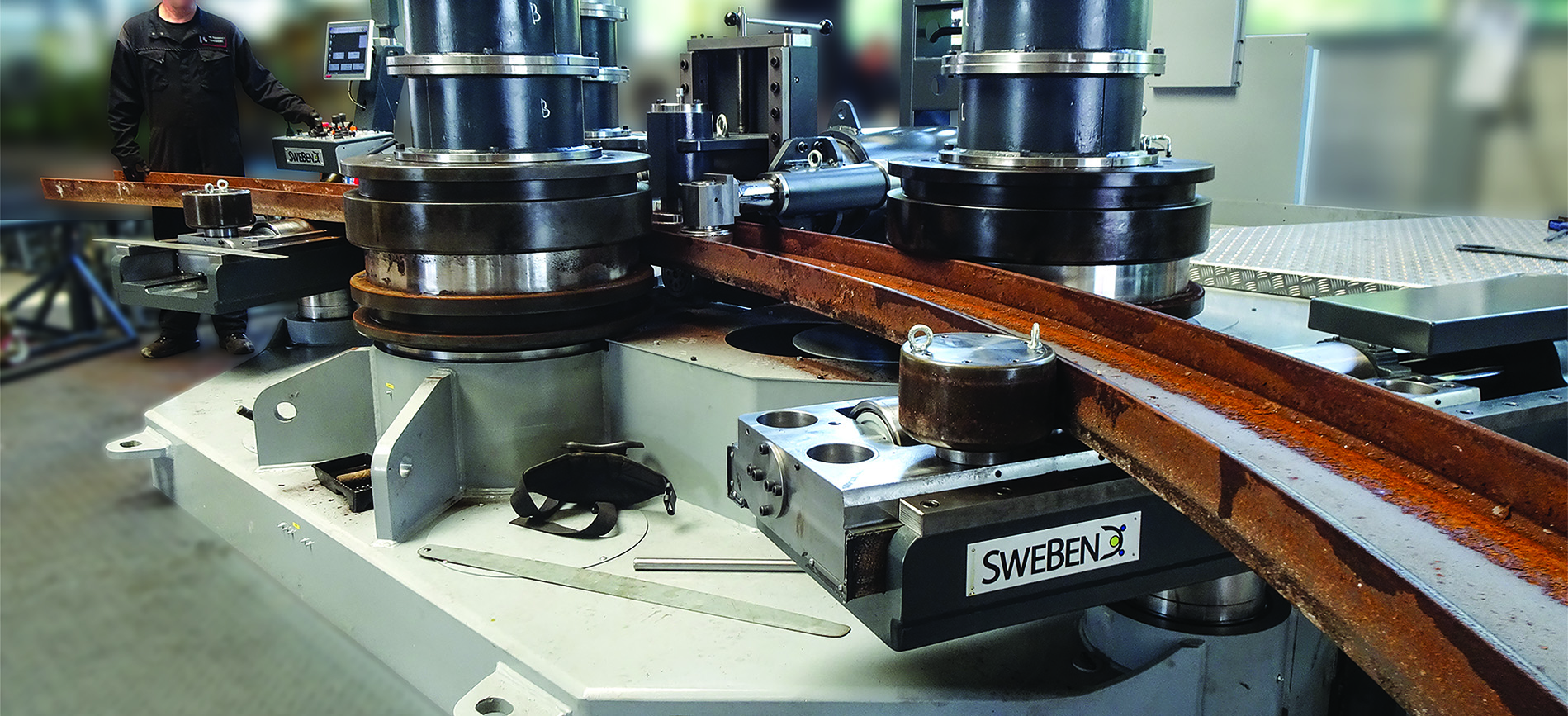

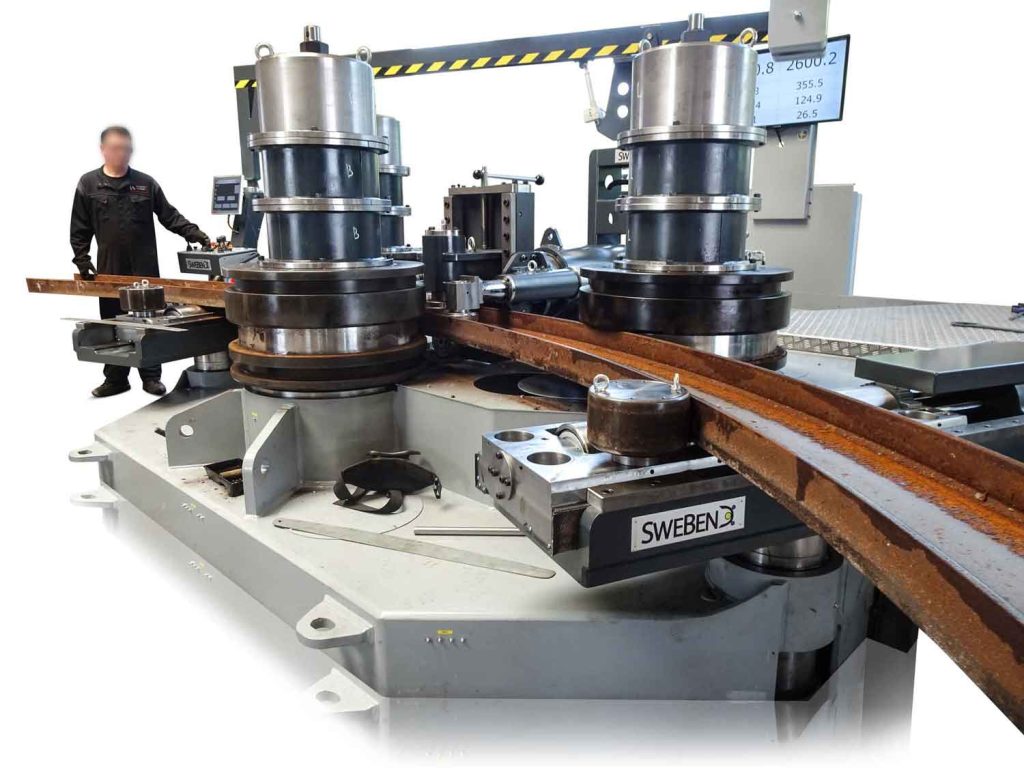

The SweBend SB3 Series

Three-Roll Double-Pinch Angle Bending Rolls

The SB3 angle roll series features guide rolls that follow the main bending rolls. The guide rolls are mechanically adjusted to support the material entering the machine and facilitate the rolling of asymmetric sections like angle iron. Operate your machine with our Bluetooth Bending Control – customized for you. The future is here! The SweBend SB3 Angle Roll will ensure your crucial position as a multifaceted bending specialist.

Standard Features

- Universal roll set for common profiles such as angle, flat bar, and T’s.

- Digital Readouts for Roll Positions

- Wireless Bluetooth Control (most models)

- Variable Speed (most models)

- Vertical or Horizontal Rolling (most models)

- Guide Rolls for rolling asymmetric shapes (manual or powered hydraulic, depending on machine size)

- High-quality commercial components, including SKF bearings

Optional Equipment

- Special roll sets for virtually any profile shape or size

- Robotic Loading and Unloading

- Turbo Package – Increased Drive Torque

- Angle Measurement System

- Dynamic Radius Adjustment System

Custom-designed angle and section rolls are also available for virtually any application. Never hesitate to ask us for advice!

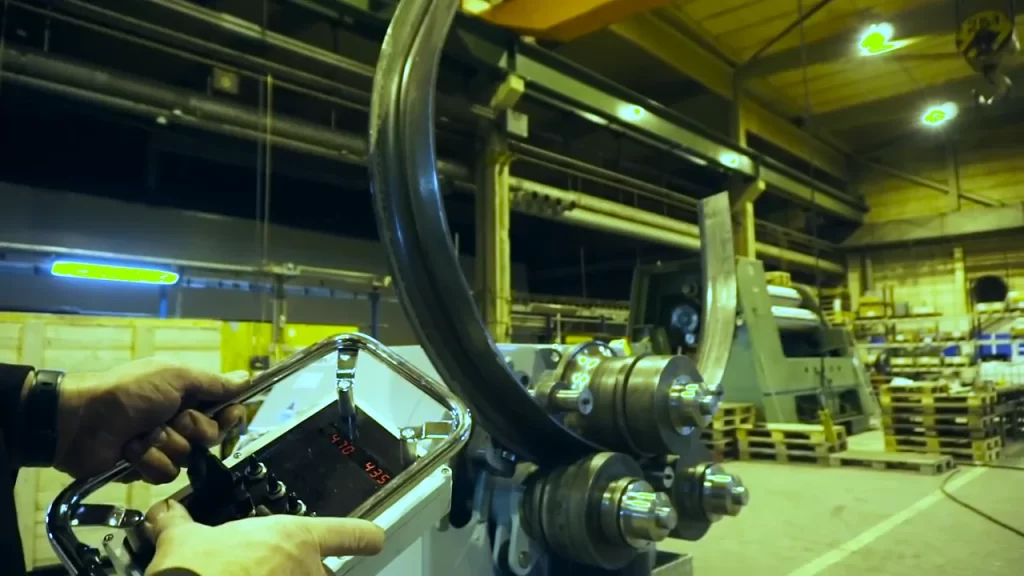

The SweBend SB4 Series

Four-Roll Double-Pinch Angle Bending Roll

The SB4 angle roll series with the SEVEN CNC system is ideal for repetitive series production. The series is powered by our unique hydraulic solution which makes it possible to interpolate ALL machines’ axes simultaneously. Create optimal results in only one pass with our double pinch bending mechanism. These machines are what “Precision Bending, Simplified” really means.

Standard Features

- Universal roll set for common profiles such as angle, flat bar, and T’s.

- Digital Readouts for Roll Positions

- Wireless Bluetooth Control (most models)

- Variable Speed (most models)

- Vertical or Horizontal Rolling (most models)

- Guide Rolls for rolling asymmetric shapes (manual or powered hydraulic, depending on machine size)

- High-quality commercial components, including SKF bearings

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

|

SWEBEND SB3B-65 Capacity: 2″ x 2″ x 5/16″ |

2″ x 2″ x 5/16″ | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Dual Execution (Vertical/Horizontal), Manual Guide Rolls. **Compatible with Roundo R-2 Tooling** |

PRICE UPON REQUEST | In Stock! |

Get a Quote |

|

SWEBEND SB3B-75 Capacity: 3″ x 3″ x 5/16″ |

3″ x 3″ x 5/16″ | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Dual Execution (Vertical/Horizontal), Manual Guide Rolls. **Compatible with Roundo R-3 and R-3S Tooling** |

PRICE UPON REQUEST | In Stock! |

Get a Quote |

|

SWEBEND SB3-85S Capacity: 3″ x 3″ x 3/8″ |

3″ x 3″ x 3/8″ | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Wireless Bluetooth Control Unit, Variable Speed, Dual Execution (Vertical/Horizontal), 6-Direction Independent Hydraulic Guide Rolls. |

PRICE UPON REQUEST | Get a Quote | |

|

SWEBEND SB3-85S CNC Capacity: 3″ x 3″ x 3/8″ |

3″ x 3″ x 3/8″ | Refurbished, 3-Roll Hydraulic Section Bending Roll. SweBend Seven GOLD CNC Control, Pneumatic Length-Measuring Wheel, Variable Speed, Dual Execution (Vertical/Horizontal), 6-Direction Independent Hydraulic Guide Rolls, |

INQUIRE FOR QUOTE | In Stock! |

Get a Quote |

|

SWEBEND SB3B-105 Capacity: 3.5″ x 3.5″ x 3/8″ Angle |

3.5″ x 3.5″ x 3/8″ Angle | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Wireless Bluetooth Control Unit, Variable Speed, Dual Execution (Vertical/Horizontal), Manual Guide Rolls. **Compatible with Roundo R-4 and R-4S Tooling** |

PRICE UPON REQUEST | In Stock! |

Get a Quote |

|

SWEBEND SB3S-105 Capacity: 4″ x 4″ x 1/2″ |

4″ x 4″ x 1/2″ | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Wireless Bluetooth Control Unit, Variable Speed, Dual Execution (Vertical/Horizontal), Hydraulic Guide Rolls. **Compatible with Roundo R-4 and R-4S Tooling** |

PRICE UPON REQUEST | Get a Quote | |

|

SWEBEND SB3S-140 Capacity: 5″ x 5″ x 1/2″ Angle |

5″ x 5″ x 1/2″ Angle | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Wireless Bluetooth Control Unit, Variable Speed, Hydraulic Guide Rolls. **Compatible with Roundo R-5, R-5S, R-52S Tooling** |

PRICE UPON REQUEST | On Order |

Get a Quote |

|

SWEBEND SB3S-180 Capacity: 6″ x 6″ x 1/2″ Angle |

6″ x 6″ x 1/2″ Angle | New, 3-Roll Hydraulic Section Bending Roll. Digital Readouts for Lower Bending Rolls, Wireless Bluetooth Control Unit, Variable Speed, Hydraulic Guide Rolls. **Compatible with Roundo R-6, R-6S, R-62S Tooling** |

SOLD | Get a Quote |