Get to know the LEMAS TR Series

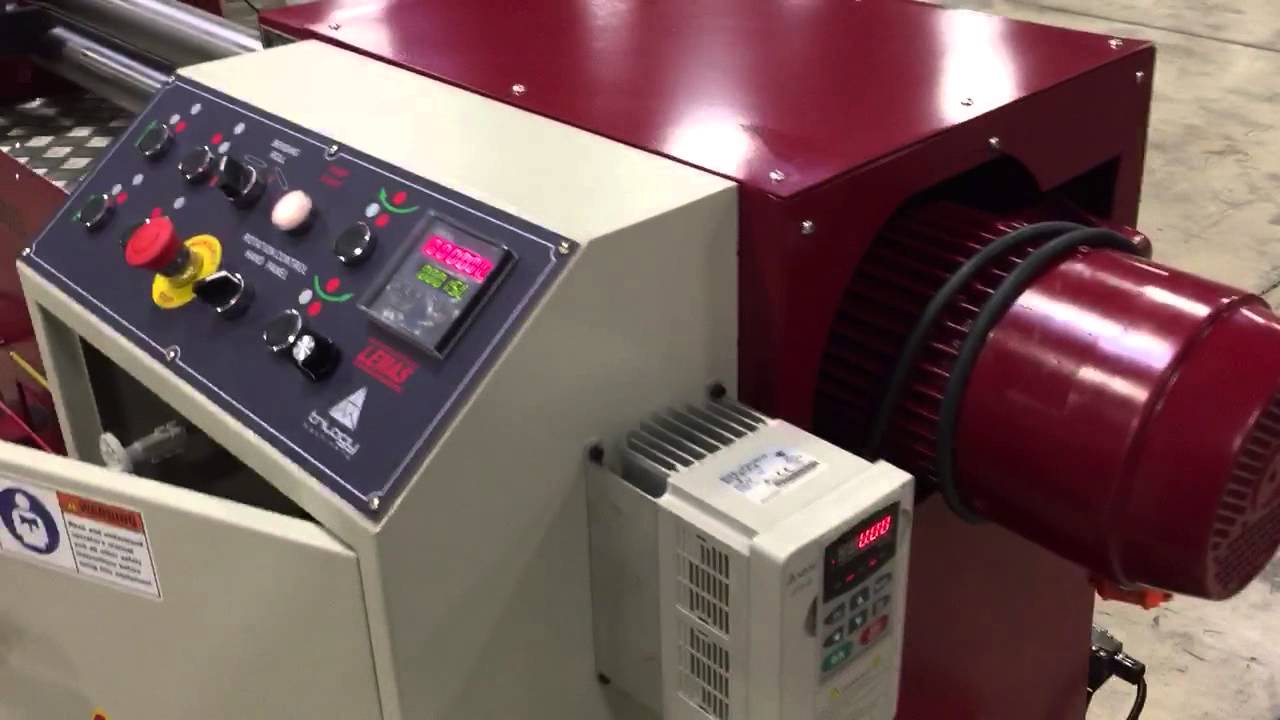

Standard Features

- -Direct-drive design using no belts or chains -Less maintenance, better performance

- -Spherical roller bearings on all rolls

- -Hydraulically powered bending roll – No manual adjustment needed.

- -Power tilting side bending roll for cone rolling – No need to manually adjust for cone bending

- -Cone bending attachment – Already integrated for your cone bending needs

- -Control panel with digital readout for the position of the side bending roll – All machine controls are easily located.

- -Hydraulically operated drop-end for quick removal of rolled product – Easy open allows you to easily slide out the finished part

- -Forward/Reverse rotation controls – Ability to walk around the entire machine while controlling rotation

- -Upper and lower pinch rolls driven

- -All rolls heat treated to 50 Rc – Keeping your rolls in peak condition as long as possible

- -Sumitomo Cyclo® 6000 gear-less speed reducers – The hardest working in the industry.

- -Manual tilt of the lower pinch roll

- -Emergency stop cable

- -Hydraulic oil, tools, training video, schematics, technical manual

Optional Equipment

- Top support

- Infinitely Variable Speed Control

- Control panel on wheels

- And more

Custom-designed plate rolls are also available. This can be a special roll diameter or roll length or even the shape of the rolls. Grooves or hardened rings enable the rolling of plates with flanges. Never hesitate to ask us for advice!

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

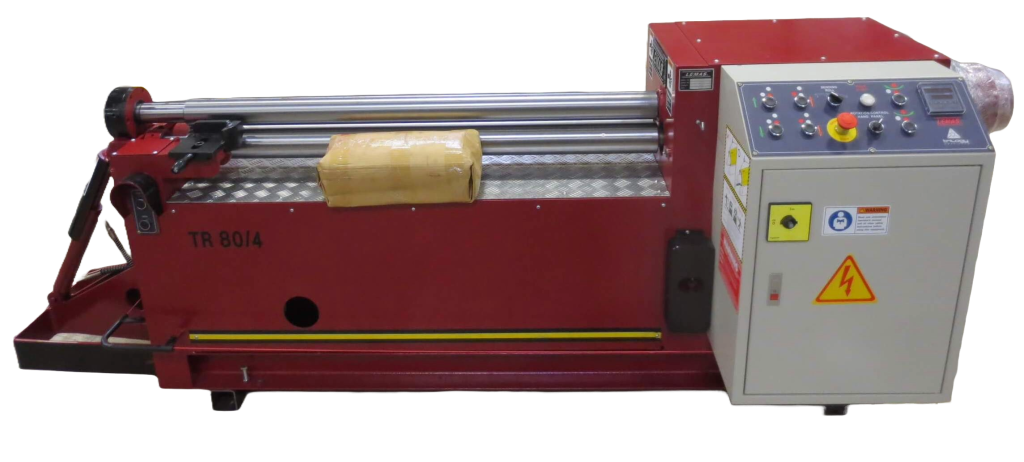

| LEMAS TR 80/3 Capacity: 3′ x 13 Ga. Mild Steel | 3′ x 13 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $23,750.00 | In Stock! | Get a Quote |

| LEMAS TR 80/4 Capacity: 4′ x 14 Ga. Mild Steel | 4′ x 14 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $23,995.00 | On Order | Get a Quote |

| LEMAS TR 100/4 Capacity: 4′ x 11 Ga. Mild Steel | 4′ x 11 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $25,995.00 | In Stock! | Get a Quote |

| LEMAS TR 120/4 Capacity: 4′ x 10 Ga. Mild Steel | 4′ x 10 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $31,500.00 | In Stock! | Get a Quote |

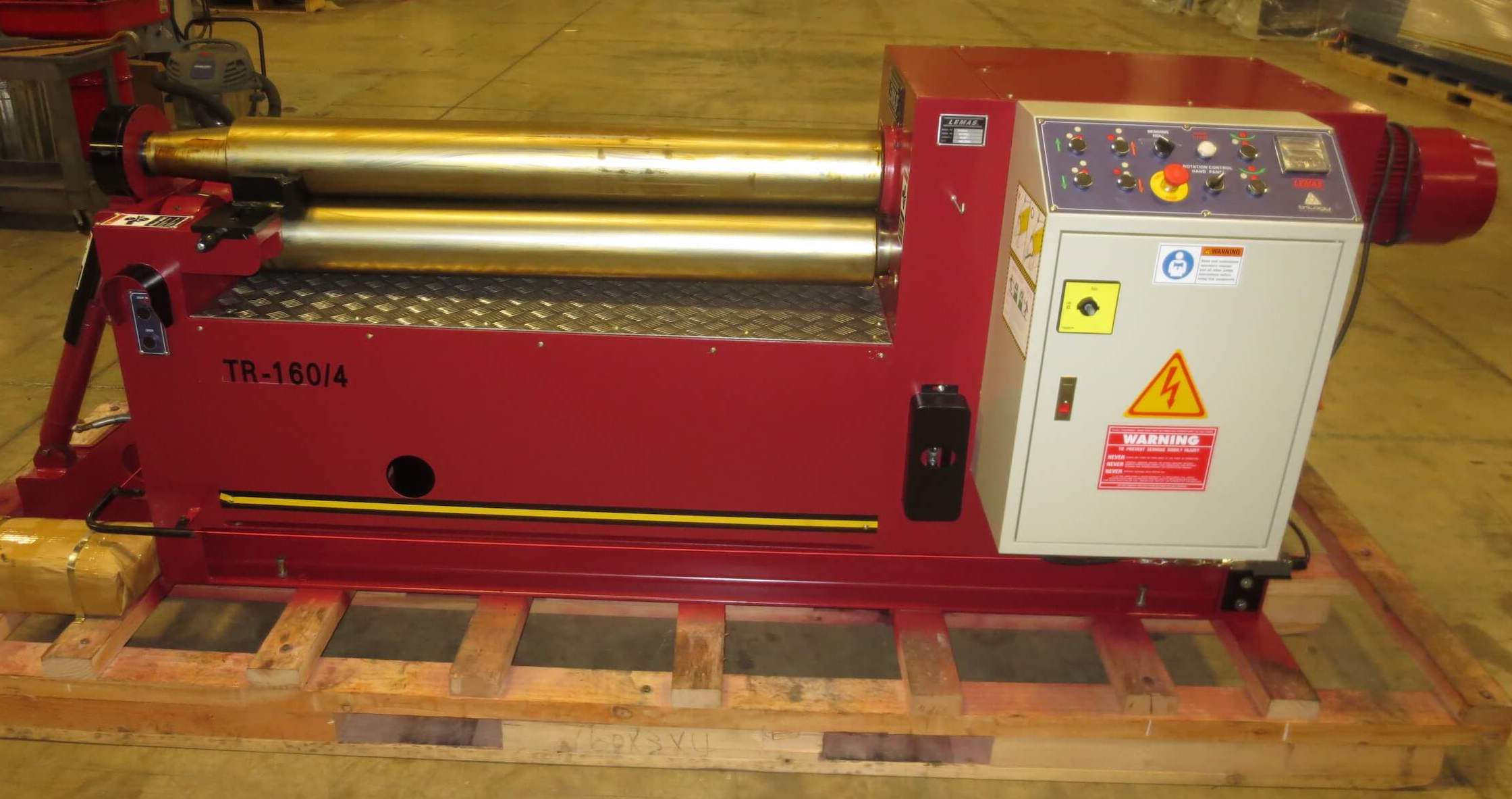

| LEMAS TR 160/4 Capacity: 4′ x 1/4″ Mild Steel | 4′ x 1/4″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $32,750.00 | On Order | Get a Quote |

| LEMAS TR 200/4 Capacity: 4′ x 9/16″ Mild Steel | 4′ x 9/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $41,500.00 | Sold | Get a Quote |

| LEMAS TR 100/5 Capacity: 5′ x 12 Ga. Mild Steel | 5′ x 12 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $26,500.00 | On Order | Get a Quote |

| LEMAS TR 120/5 Capacity: 5′ x 10 Ga. Mild Steel | 5′ x 10 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $31,995.00 | On Order | Get a Quote |

| LEMAS TR 140/5 Capacity: 5′ x 3/16″ Mild Steel | 5′ x 3/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $32,995.00 | Sold | Get a Quote |

| LEMAS TR 160/5 Capacity: 5′ x 1/4″ Mild Steel | 5′ x 1/4″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $33,750.00 | In Stock! | Get a Quote |

| LEMAS TR 180/5 Capacity: 5′ x 5/16″ Mild Steel | 5′ x 5/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $37,995.00 | Sold | Get a Quote |

| LEMAS TR 200/5 Capacity: 5′ x 1/2″ Mild Steel | 5′ x 1/2″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $43,995.00 | In Stock! | Get a Quote |

| LEMAS TR 160/6 Capacity: 6′ x 3/16″ Mild Steel | 6′ x 3/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $35,750.00 | Inquire / Ask Us! | Get a Quote |

| LEMAS TR 180/6 Capacity: 6′ x 1/4″ Mild Steel | 6′ x 1/4″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $41,995.00 | In Stock! | Get a Quote |

| LEMAS TR 200/6 Capacity: 6′ x 3/8″ Mild Steel | 6′ x 3/8″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $45,995.00 | On Order | Get a Quote |

| LEMAS TR 180/8 Capacity: 8′ x 3/16″ Mild Steel | 8′ x 3/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $44,995.00 | Get a Quote | |

| LEMAS TR 200/8 Capacity: 8′ x 5/16″ Mild Steel | 8′ x 5/16″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $51,995.00 | On Order | Get a Quote |

| LEMAS TR 180/10 Capacity: 10′ x 10 Ga. Mild Steel | 10′ x 10 Ga. Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $52,250.00 | Get a Quote | |

| LEMAS TR 200/10 Capacity: 10′ x 1/4″ Mild Steel | 10′ x 1/4″ Mild Steel | New, Direct-Drive, 3-Roll, Initial Pinch, Digital Readout, Hardened Rolls, Cone Bending Attachment and More! | $57,995.00 | Get a Quote |