ROLL BETTER:

Refurbished Bending Rolls

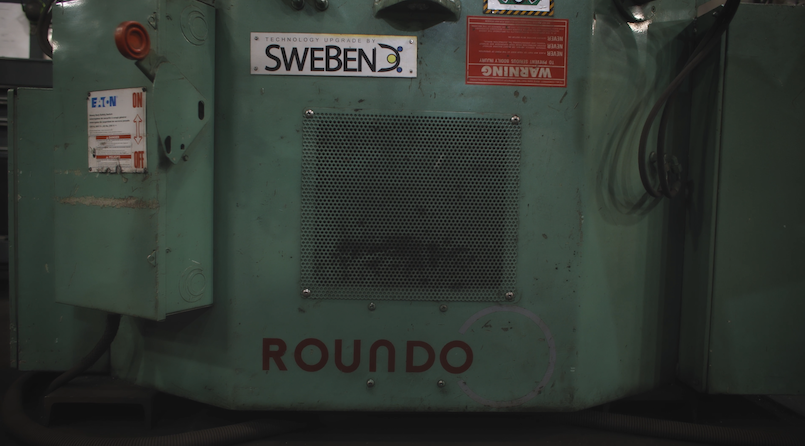

Trilogy Machinery refurbishes and revitalizes old Roundo Plate and Angle Bending Rolls

Our staff of technicians is on hand to complete the revitalization of your Roundo Plate or Angle Bending Roll.

Our modern facility, just north of Baltimore, is capable of handling virtually any size machine.

Our 25 -Ton Crane, state-of-the-art paint booth, wash bay, and 30′ high warehouse allows us to give your machine the attention it deserves.

With over $1,500,000 of OEM parts in-stock, in many cases, our turnaround time is as little as one week.

Trilogy is confident that with continual maintenance and revitalization, your bending roll will continue to function at peak performance for years to come.

We look forward to speaking with you about our process and your machine.

PLEASE NOTE:

During the change in Roundo ownership and closure in Sweden, Trilogy Machinery purchased the OEM parts inventory from Roundo.

Trilogy now has the largest supply of Roundo OEM parts in the world.

We will continue to support our customers’ needs, and transition them to the leader in Swedish Bending Rolls: SweBend.

The Trilogy Machinery In-House Revitalization Process

Initial Review Includes:

- Thorough inspection by a lead Trilogy Machinery technician, Parts Manager, and Operations

- Oil and fluid drain, environmental disposal, flush and change, and lubrication

- Leak detection, operation (if possible), and system pressure check

Complete In-House Revitalization Process:

Upon completion of the basic revitalization process, we will make recommendations for further upgrades and modifications, such as:

- Updating all CNC and PLC hardware and software to latest versions including Windows OS, or completely overhauling the CNC system to the latest SweBend software and interface

- Replacing mechanical components due to wear and tear

- Installing digital read-outs, or bluetooth controller

- Replacing bearings

- Rebuilding or replacing hydraulic cylinders

- Updating or replacing electrical components

- Installing or rebuilding pumps and hydraulic motors

- Additional options based on individual customer

We are obligated to advise you that Roundo® is a registered trademark of Boldrini S.R.L. and that Boldrini has not formally designated Trilogy Machinery as an authorized dealer or service provider for Roundo® parts.