Sunrise APS Series

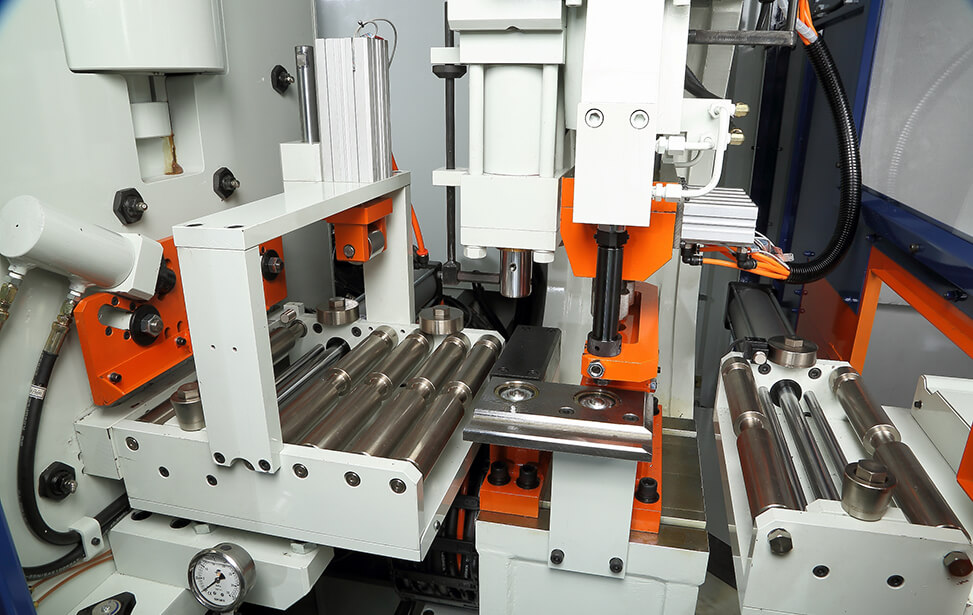

Automatic Plate Processing System

Get to know the APS Series

Standard Features

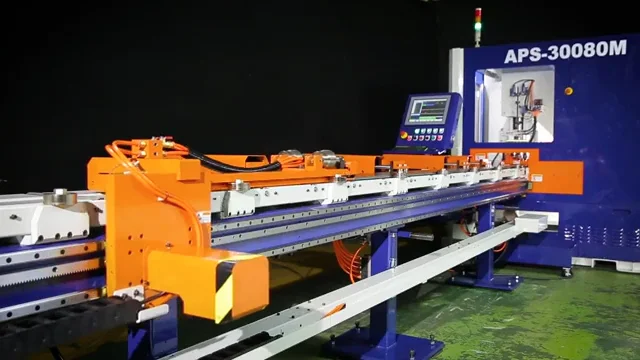

- Rack and Pinion Drive System, expandable up to 50′.

- Hydraulic hold-down for shearing

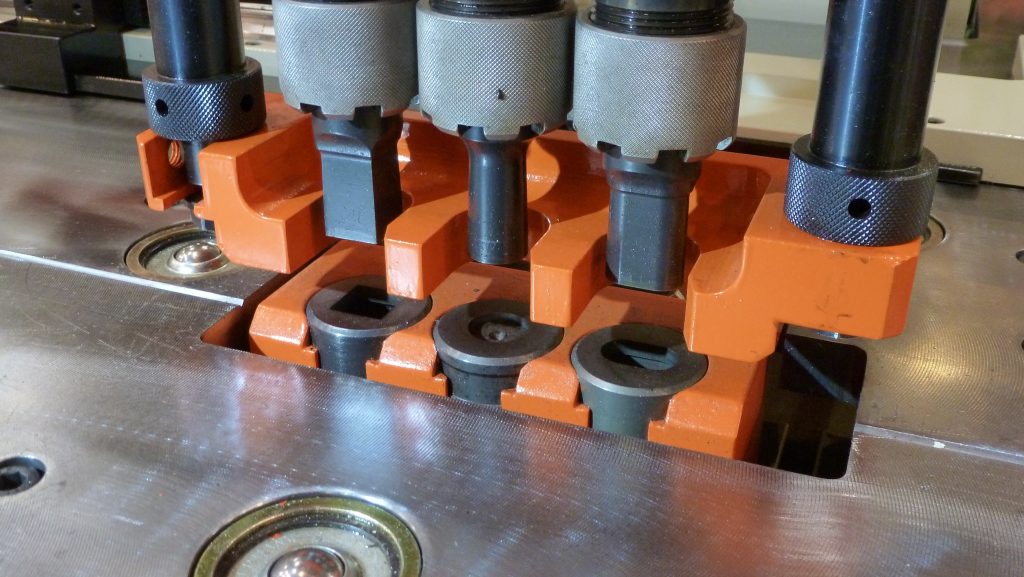

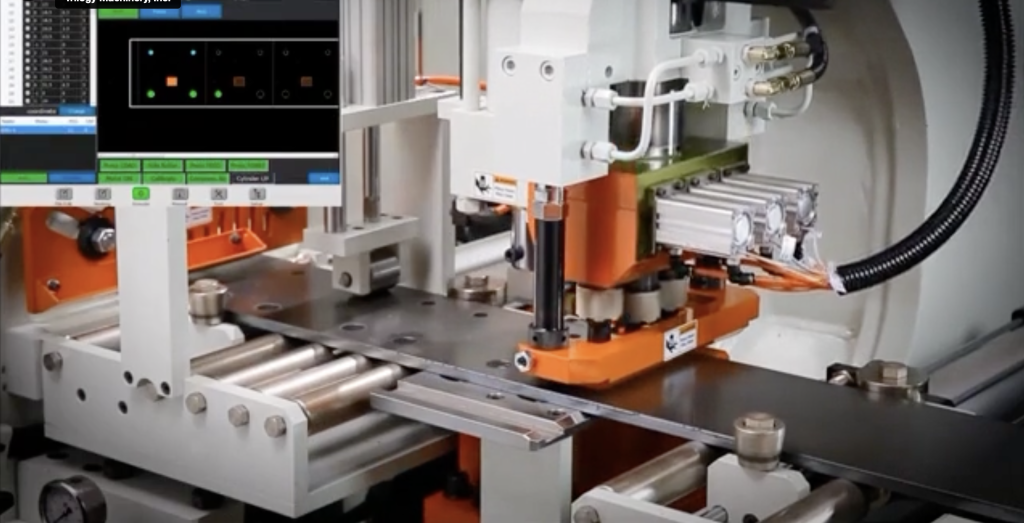

- Triple punch feature with a hydraulic stripper – 1.5″ capacity center punch, 1.125″ side punches, individually controlled

- Adjustable guide rollers for squareness

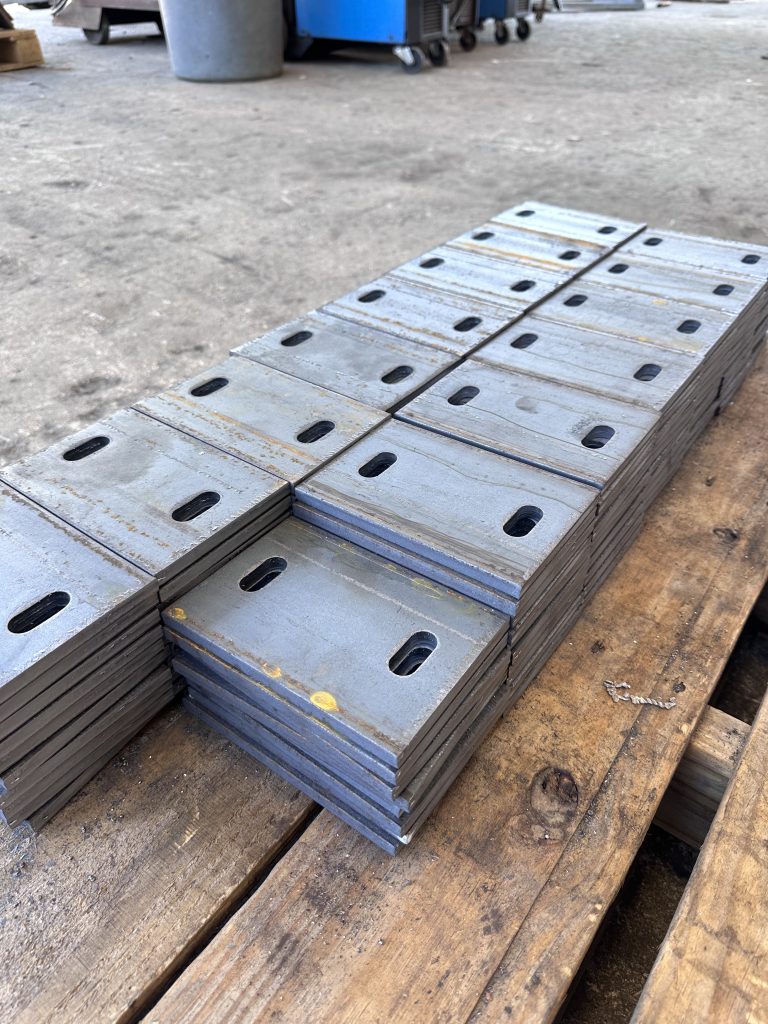

- Anti-twist sheet support system ensures square cuts on every sheared part with no slug loss and only 6″ scrap per run.

- Automatic pneumatic material clamping and squaring

- Fully enclosed punching and shearing operations for operator safety

- Integrated hydraulic oil cooling system

Optional Features

- Light Curtain Safety System

- Additional sections of automated in-feed

- Part Stamp/Dot Peen Marking

- Multi-Seat Software License

- Single-Punch Option

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

|

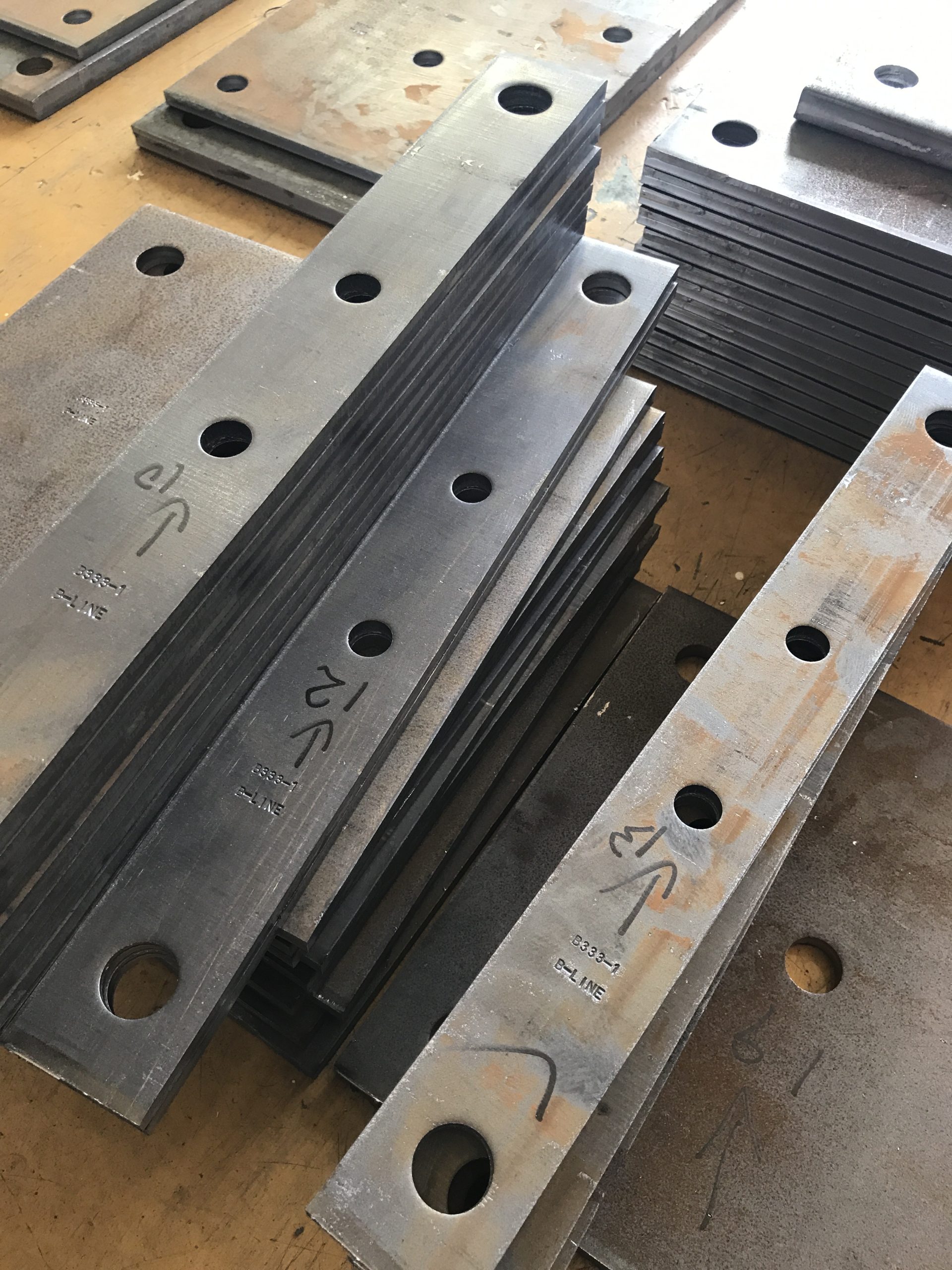

Sunrise APS 30080M – Plate System Capacity: Plate Processing Line | Triple -Punches | 12″ x 3/4″ Flat Bar | Rack and Pinion System |

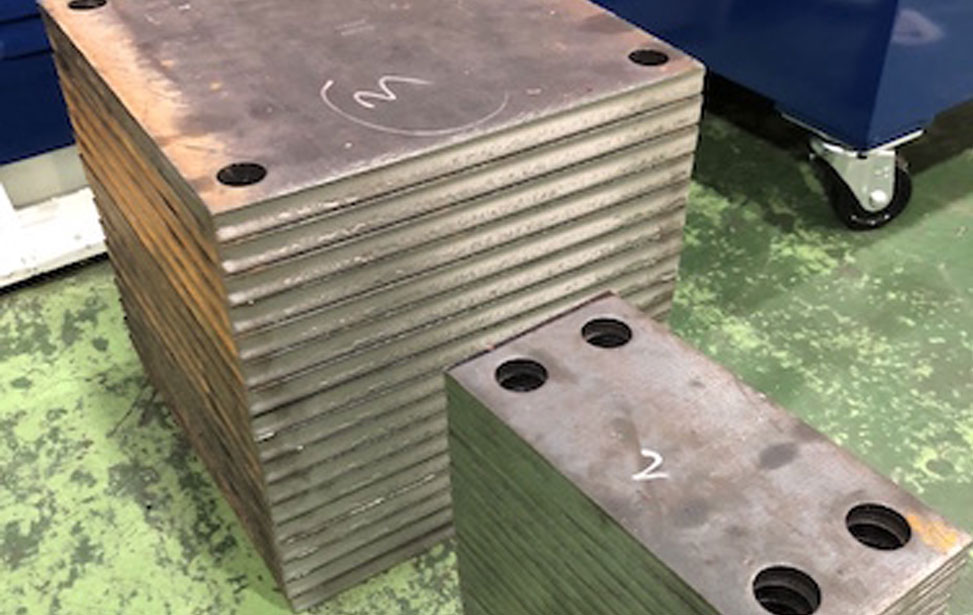

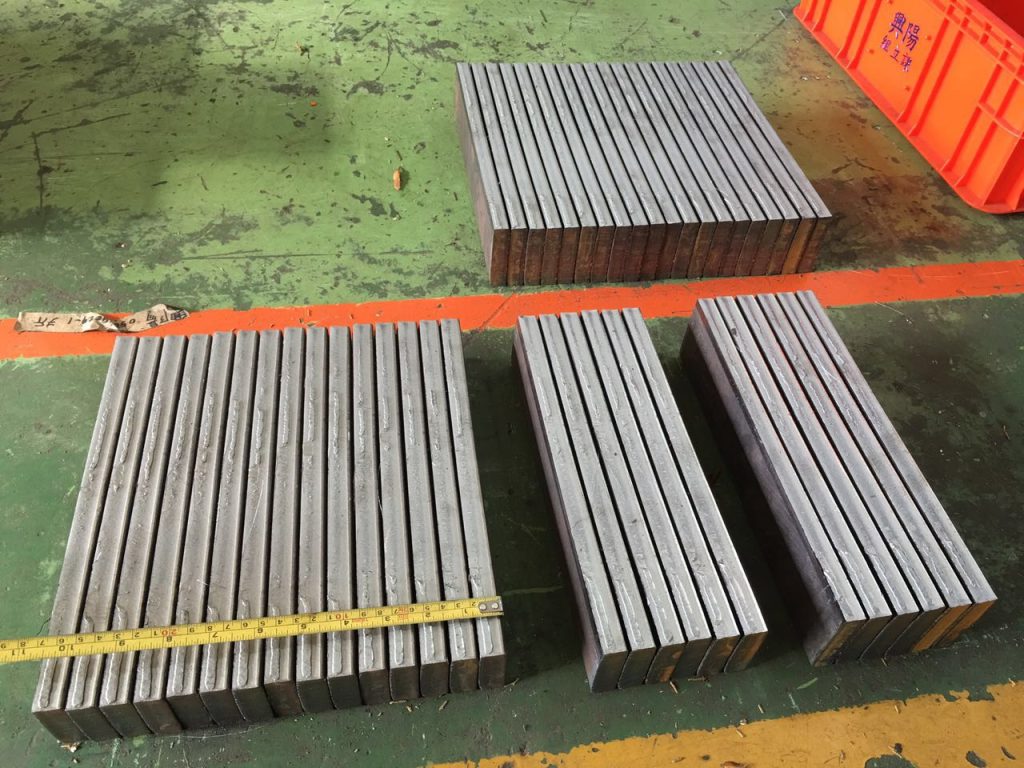

Plate Processing Line | Triple -Punches | 12″ x 3/4″ Flat Bar | Rack and Pinion System | New, Plate Processing System, 20′ Rack and Pinion In-Feed, 12″ x 3/4″ Flat Bar Capacity, 88-ton Punching Cylinder, 170-Ton Shearing Cylinder, Triple-Punch Heads featuring 3 independent Punches, and more! |

$224,950.00 – 20 Foot system | On Order |

Get a Quote |