Get to know the HBM Series

Standard Features

- Touch screen controller with 50 program memory

- Manual back gauge

- 3″ single vee die and punch

- 2 Year Warranty on Parts

Optional Features

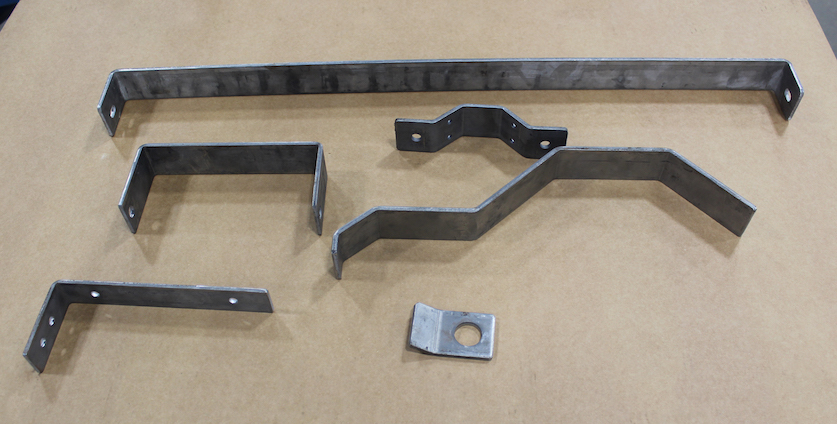

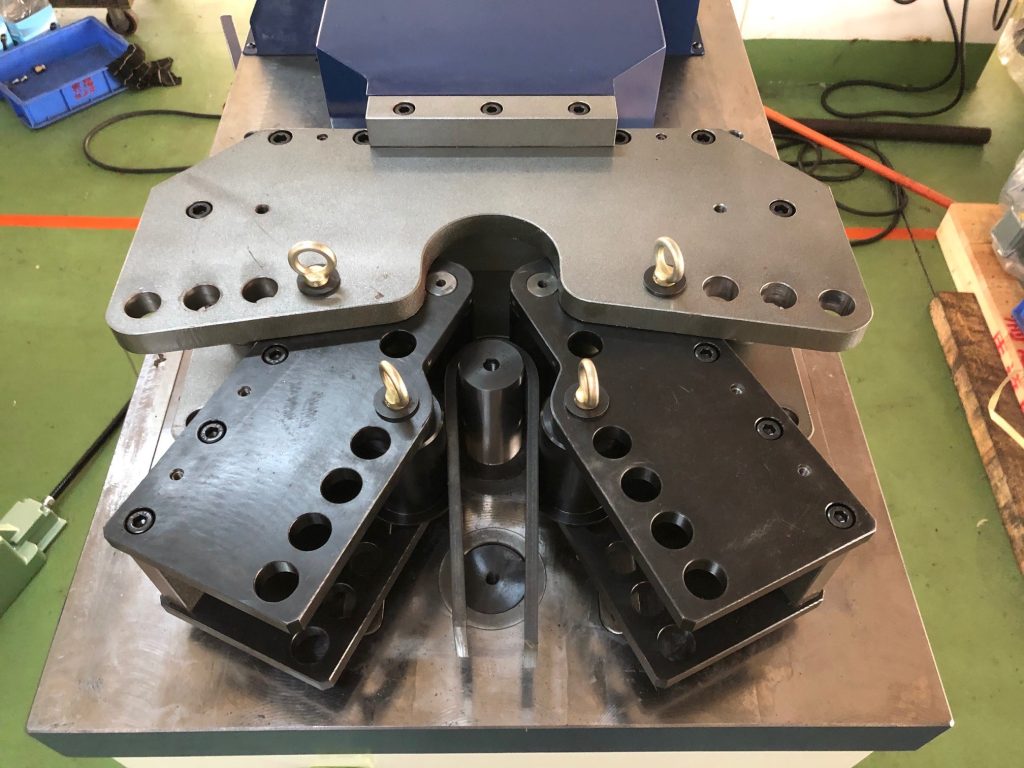

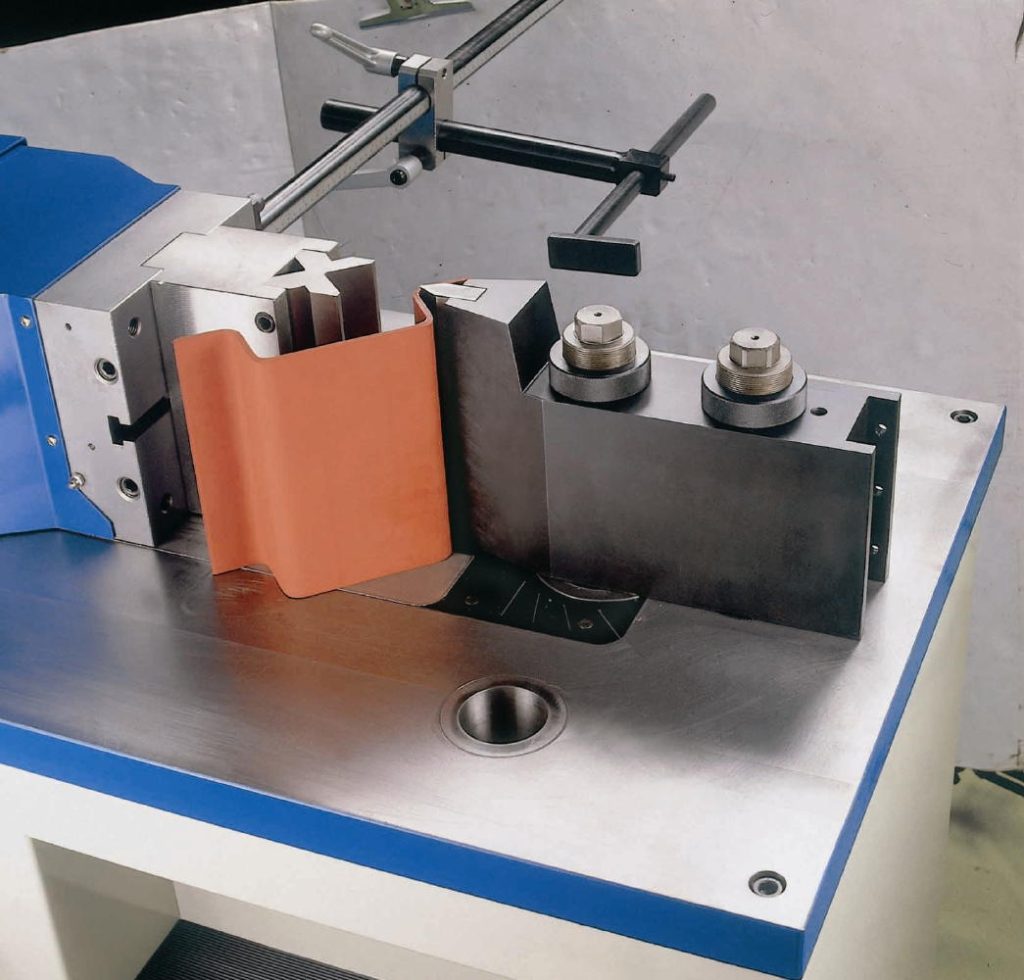

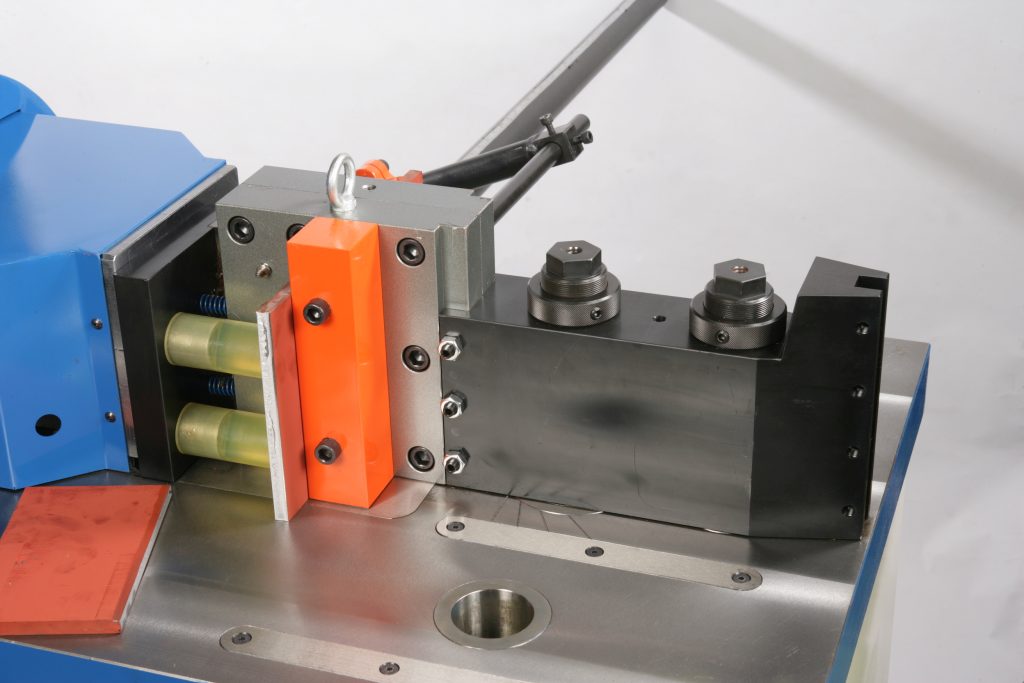

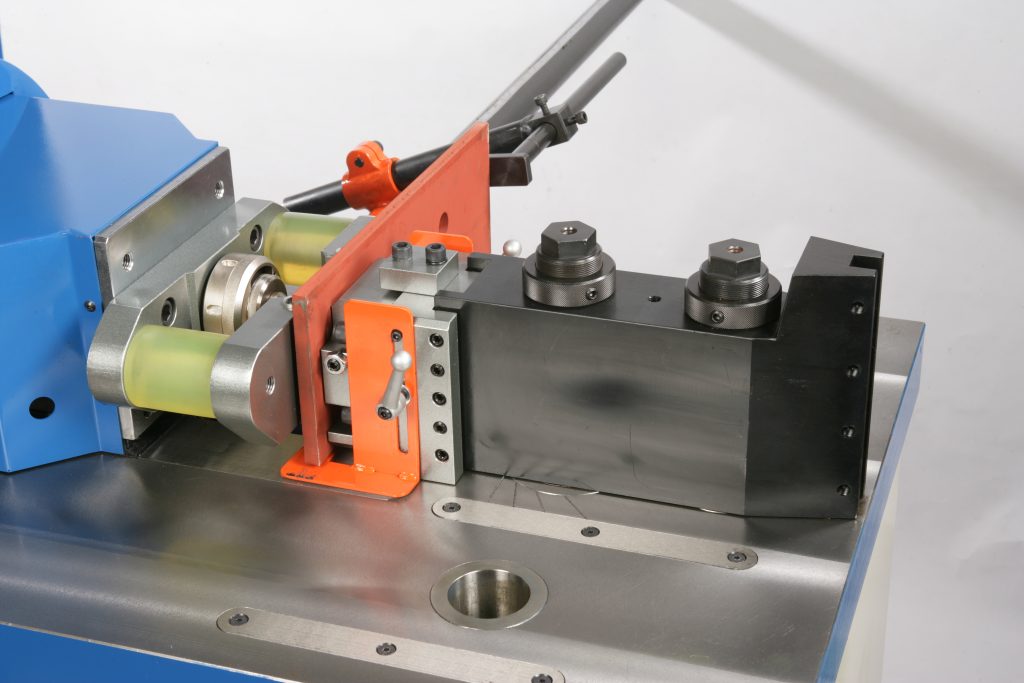

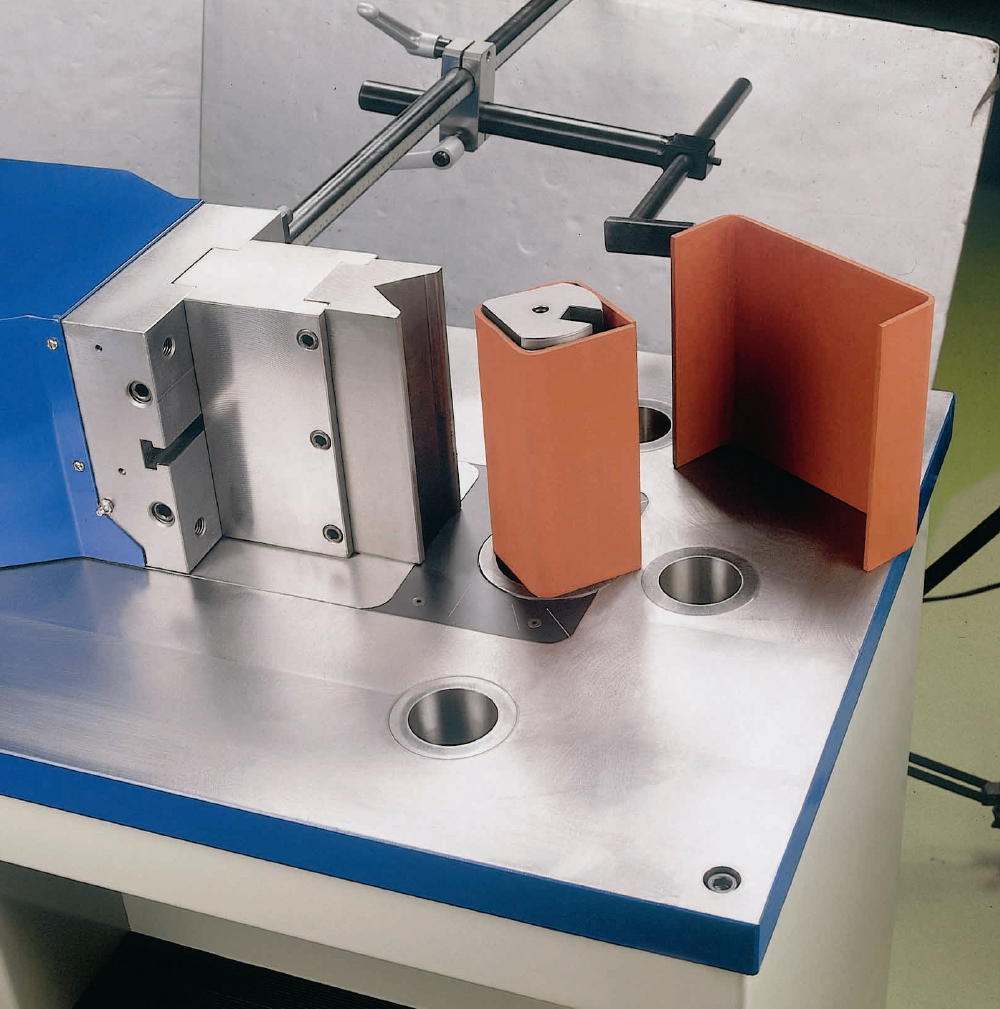

- Single and multi-dies

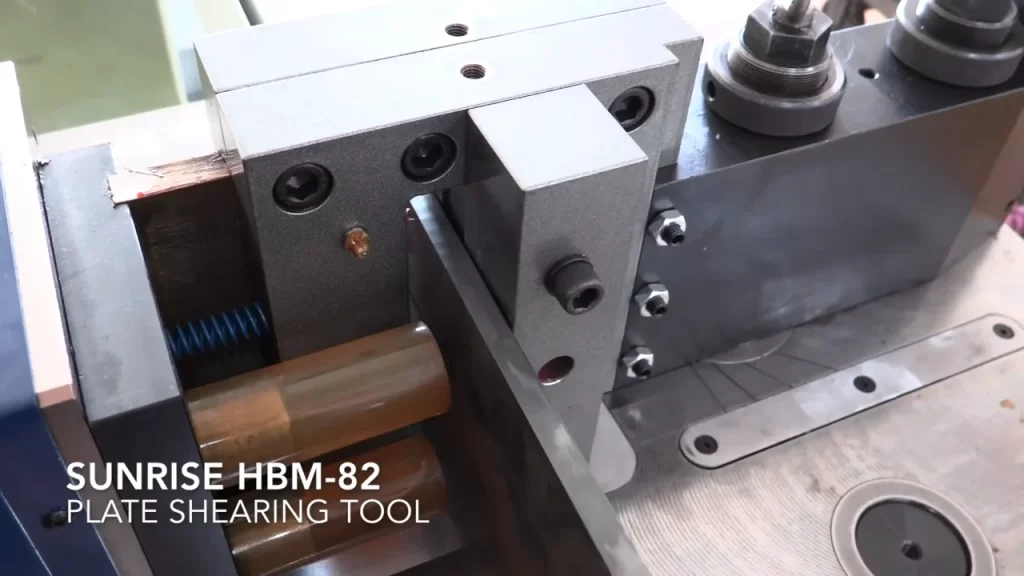

- Flat bar bending, pipe bending, punching, shearing

- CNC back gauges

- Custom tooling

HBM CNC Backgauge

The CNC back gauge extends the accuracy and efficiency of the HBM and is available in both 1m and 2m configurations. With an accuracy of ±0.004″ and 40’/min travel speed, when combined with the digitally controlled cylinder travel, achieves complex bending work with ease. Control memory can store up to 99 programs with 10 bends each for quick and easy programming of multiple jobs.

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

|

SUNRISE HBM-45 – Horizontal Bending Machine Capacity: 45 Tons – 8″ x 1/2″ Capacity |

45 Tons – 8″ x 1/2″ Capacity | New, Horizontal Bender, Programmable Controller, Manual Back-Gauge, 10″ stroke, 2 year warranty. |

$27,995.00 | In Stock! |

Get a Quote |

|

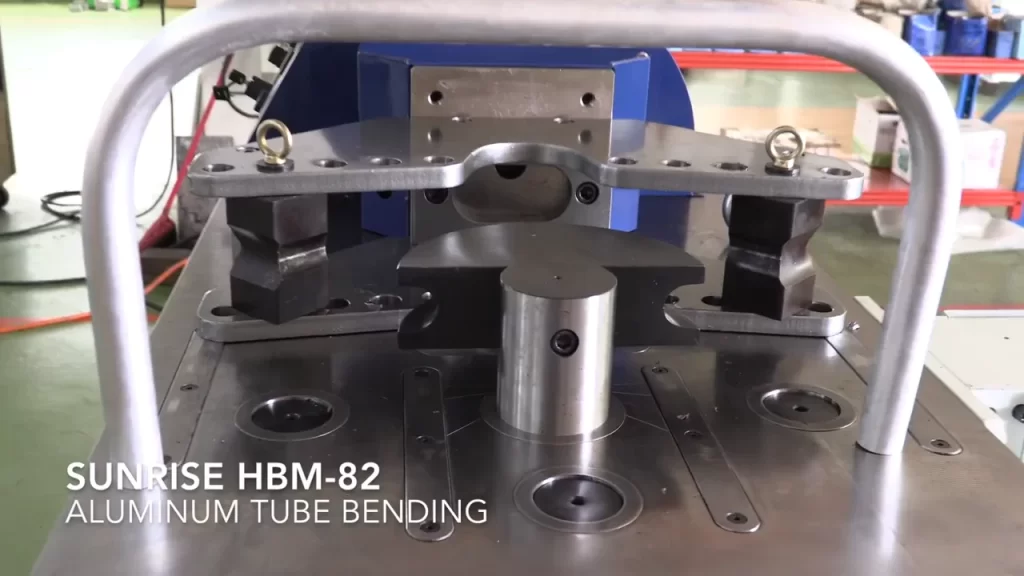

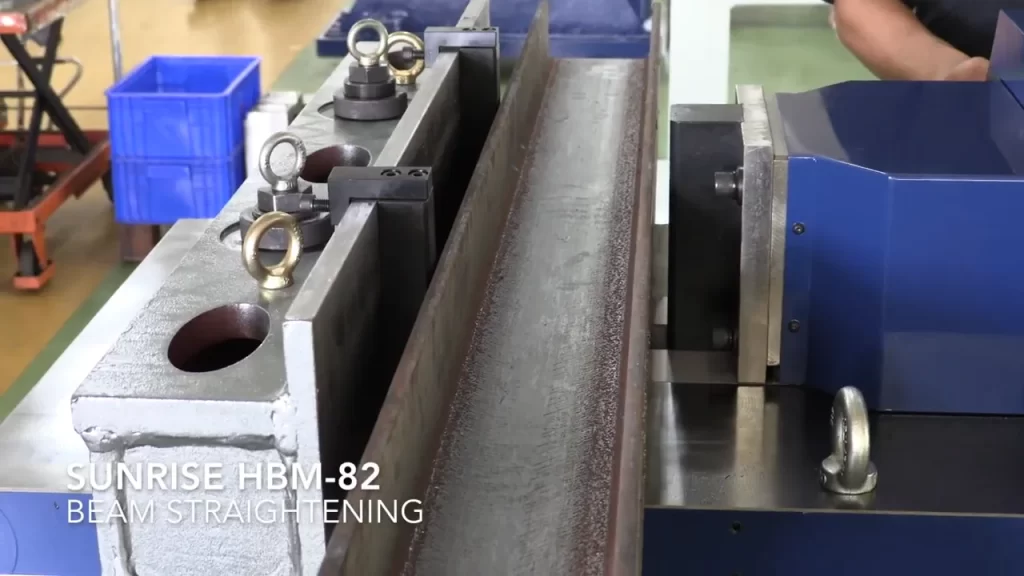

SUNRISE HBM-82 – Horizontal Bending Machine Capacity: 82 Tons – 12″ x 1/2″ Capacity |

82 Tons – 12″ x 1/2″ Capacity | New, Horizontal Bender, Programmable Controller, Manual Back-Gauge, 14″ stroke, 2 year warranty. |

$44,495.00 | In Stock! |

Get a Quote |

|

SUNRISE HBM CNC Capacity: HBM-45 or HBM-82 |

HBM-45 or HBM-82 | 1 or 2m CNC Back Gauge for the Sunrise HBM-45 or HBM-82. |

$19,950.00 | In Stock! |

Get a Quote |