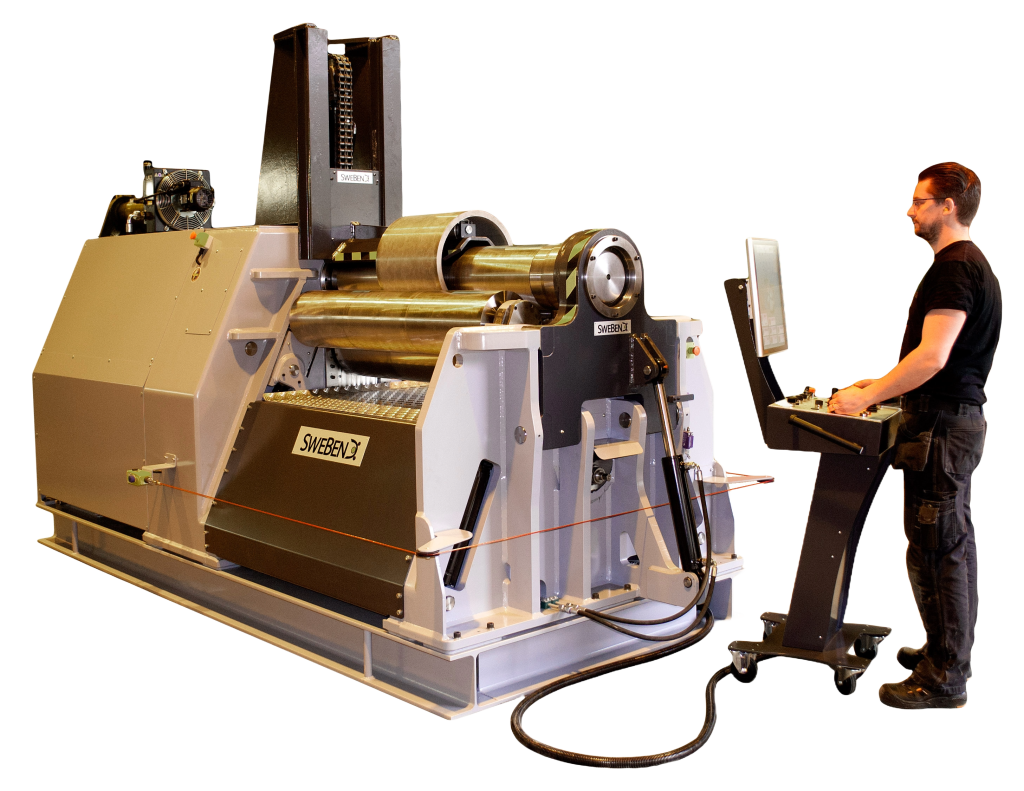

The PB-4 Series

Four-Roll Plate Bending Roll

Standard Features

- All Hydraulic Operation

- Precision Hardened & Ground Rolls

- High-quality commercial components, including SKF bearings

- Wireless Bluetooth Control Unit

- Variable Speed

- Digital Readouts for both ends of each bending roll (4 in total)

- Hydraulic drop end with tilt-up top roll for easy part removal

- Electronic Control of Roll Parallelism

Optional Equipment

- Cone bending attachment

- CNC Controls

- Robot – Automatic Infeed Tables

- Automatic Loading System

- Automatic Sheet Flipper

- Bar Code Scanner

- Turbo Package – Increased Drive Torque

- And more

Custom-designed plate rolls are also available. This can be a special roll diameter, roll length, or even shape of the rolls. Never hesitate to ask us for advice!

| Model | Capacity | Description | Price | Status | Info | |

|---|---|---|---|---|---|---|

|

SWEBEND PB4-8-6 CNC Capacity: 6′ x 3/8″ Mild Steel |

6′ x 3/8″ Mild Steel | New, 4-Roll, Hydraulic Drive, Variable Speed, Hardened & Ground Rolls, Cone Bending, Hydraulic Lifting Roll, Powered Support Rolls Under Lower Roll, Multi-axis SEVEN GOLD CNC Control |

PRICE UPON REQUEST | In Stock! |

Get a Quote |